I-Comact Wheat Flour Mill

Intshayelelo emfutshane:

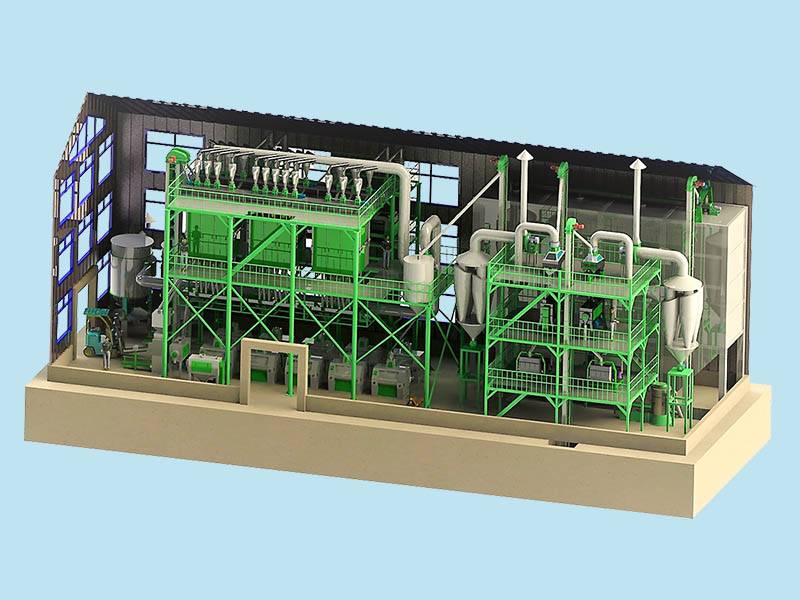

I-Flour Mill Equipment yomatshini wokusila umgubo wengqolowa weCompact kwisityalo sonke ziyilelwe kwaye zifakwe kunye nenkxaso yesakhiwo sentsimbi.Isakhiwo esisisiseko senkxaso senziwe ngamanqanaba amathathu: i-roller mills ibekwe kumgangatho ophantsi, i-sifters ifakwe kumgangatho wokuqala, i-cyclones kunye neepayipi ze-pneumatic zikumgangatho wesibini.

Izinto ezivela kwii-roller Mills ziphakanyiswa yi-pneumatic transfering system.Imibhobho evaliweyo isetyenziselwa ukungena komoya kunye nokususa uthuli.Ubude beworkshop buphantsi ngokwentelekiso ukunciphisa utyalo-mali lwabathengi.Itekhnoloji yokugaya ingahlengahlengiswa ukuze yanelise iimfuno ezahlukeneyo zabathengi.Inkqubo yolawulo ye-PLC ekhethwayo inokuqonda ulawulo olusembindini kunye nenqanaba eliphezulu lokuzenzela kwaye yenze umsebenzi ube lula kwaye ube bhetyebhetye.Ukungena komoya ovalelweyo kunokuthintela ukuchitheka kothuli ukugcina imeko ephezulu yokusebenza yococeko.Ilitye lokusila lonke linokufakwa ngokudibeneyo kwindawo yokugcina impahla kwaye uyilo lunokwenziwa ngokweemfuno ezahlukeneyo.

Iinkcukacha zeMveliso

Iithegi zeMveliso

Ividiyo yemveliso

Ingcaciso yeMveliso

ICANDELO LOKUCOCA

.jpg)

Kwicandelo lokucoca, samkela iteknoloji yokucoca uhlobo lokumisa, ngokuqhelekileyo ibandakanya ukuhluzwa kwamaxesha ama-2, ukuhluzwa kwamaxesha ama-2, ukucolwa ngamatye, ukuhlanjululwa kwamatye, ukuhlanjululwa kwamaxesha ama-4, amaxesha ama-1 ukuya kuma-2 ukudambisa, ukuhlukana kwamagnetic amaxesha amathathu njalo njalo. Kwicandelo lokucoca, kukho iinkqubo ezininzi ezinqwenelekayo ezinokunciphisa uthuli olutshizwayo oluphuma kumatshini kwaye lugcine indawo elungileyo yokusebenza. Eli liphepha elintsonkothileyo lokuqukuqela elinokususa uninzi lweoffal erhabaxa, ubungakanani obuphakathi kunye neoffal ecolekileyo. kwingqolowa.Icandelo lokucoca alifanelekanga kuphela ingqolowa ethunyelwa ngaphandle kunye nokufuma okuphantsi kwaye ifanelekile ingqolowa engcolileyo evela kubathengi basekhaya.

ICANDELO LOMILLING

.jpg)

Kwicandelo lokusila, kukho iintlobo ezine zeenkqubo zokusila ingqolowa ibe ngumgubo. Ziyi-4-Break system, 7-Reduction system, 1-Semolina system kunye ne-1-Tail system.Izihlambululi zenzelwe ngokukodwa ukufumana i-semolina esulungekileyo ithunyelwe. ukuya kuNciphiso oluphucula umgangatho womgubo ngomda omkhulu.Iirola zokuNcitshiswa, iSemolina, kunye neenkqubo zoMsila ziirola ezigudileyo eziqhume kakuhle. Uyilo lonke luya kukuqinisekisa ukuba i-bran encinci ixutywe kwibran kwaye isivuno somgubo sikwandiswa. inkqubo yokuphakamisa i-pneumatic eyilwe kakuhle, yonke into yokusila ihanjiswa yiFan yoxinzelelo oluphezulu.

Yonke imitshini yokupakisha i-automatioc.Umatshini wokupakisha uneempawu zokuchaneka kokulinganisa okuphezulu, ukukhawuleza ukupakisha ukupakisha, ukuthembeka kunye nokusebenza okuzinzile.Inokulinganisa kwaye ibale ngokuzenzekelayo, kwaye inokuqokelela ubunzima.Umatshini wokupakisha unomsebenzi wokuzixilonga ngempazamo. Umatshini wokuthunga unomsebenzi wokuthunga ngokuzenzekelayo kunye nokusika.Umatshini wokupakisha unoluhlobo olutywiniweyo lwe-bag-clamping mechanism, enokuthintela izinto eziphuma ngaphandle.Inkcazo yokupakisha ibandakanya i-1-5kg, 2.5-10kg, 20-25kg, 30-50kg. Abaxumi banokukhetha ukupakisha okungafaniyo ngokweemfuno.

Kule nxalenye, siya kubonelela ngekhabhinethi yokulawula umbane, intambo yesignali, iitreyi zentambo kunye neeleli zentambo, kunye nezinye iindawo zokufakelwa kombane. Kwinkqubo yolawulo ye-PLC, bonke oomatshini balawulwa nguMlawuli oyiProgrammed Logical Controller onokuqinisekisa ukuba umatshini osebenza ngokuzinzileyo nangokutyibilikayo. I-alam kwaye ukhumbuze umqhubi ukuba alungise iimpazamo. Uluhlu lweendawo zombane zeSchneider zisetyenziswa kwikhabhathi yombane. Uphawu lwe-PLC luya kuba yi-Siemens, i-Omron, i-Mitsubishi kunye nezinye i-Brand yamazwe ngamazwe. ihamba kakuhle.

ULUHLU LWEPARAMETER YOBUGCISA

| Ilungisiwe | Umthamo(t/24h) | Roller Mill Moded | Imodeli yeSifter | Isithuba LxWxH(m) |

| CTWM-40 | 40 | Imanyuwali | Twin Sifter | 30X8X11 |

| CTWM-60 | 60 | Imanyuwali | Twin Sifter | 35X8X11 |

| CTWM-80 | 80 | Umoya | Cwangcisa iSifter | 38X10X11 |

| CTWM-100 | I-100 | Umoya | Cwangcisa iSifter | 42X10X11 |

| CTWM-120 | 120 | Umoya | Cwangcisa iSifter | 46X10X11 |

| CTWM-150 | 150 | Umoya | Cwangcisa iSifter | 50X10X11 |

Ukupakisha kunye nokuhanjiswa

>

>