Flour Milling Equipment Isitshabalalisi sezinambuzane

Intshayelelo emfutshane:

Izixhobo zokusila umgubo izinambuzane umtshabalalisi isetyenziswa ngokubanzi kwiindawo zokusila zomgubo zanamhlanje ukwandisa ukutsalwa komgubo kunye noncedo lokusila.

Iinkcukacha zeMveliso

Iithegi zeMveliso

Ividiyo yemveliso

Ingcaciso yeMveliso

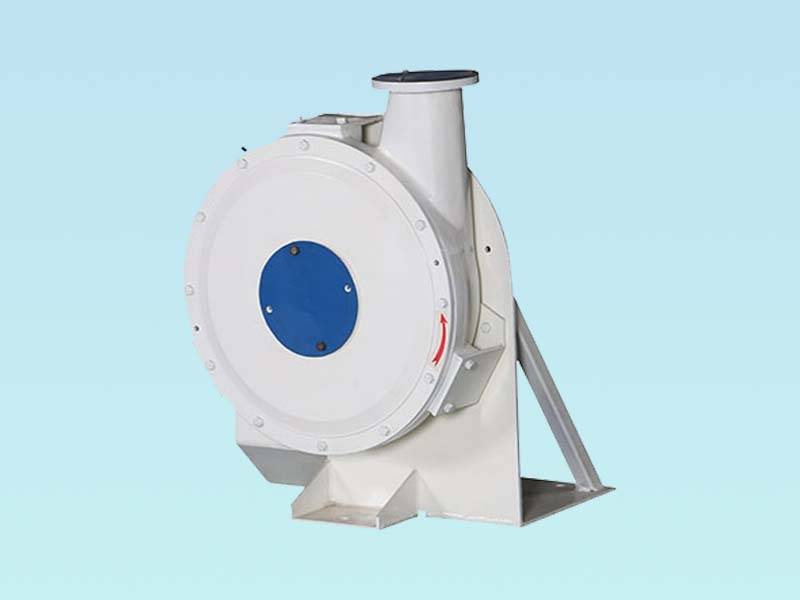

Isithinteli sethu sempembelelo ehlala ixesha elide kukuphucula izinga lokutsalwa komgubo kwiplanti yokugaya umgubo.Ngee-rotors ezikhawulezayo, inokutyumza ii-endosperm flakes, ngakumbi iiflakes eziphantsi kwee-roller ezigudileyo.Ngaloo ndlela umsebenzi wokusefa unokwandiswa ukusa kwinqanaba elithile.Ngaphandle koko, eli nyathelo linokubulala iibhugi kwaye linqande amaqanda e-bug kunye nombungu ekukhuleni, kwaye ugcine iigranules kwimeko ethambileyo.

Umgaqo Womsebenzi

Lo matshini wenzelwe ukukhupha amasuntswana endosperm emva kokunciphisa ukugaya ngeerola ezigudileyo ukuze kwandiswe ukutsalwa komgubo kwiindawo zokusila zomgubo.Umatshini ojikelezayo ubandakanya izindlu zentsimbi kunye ne-motor flanged efakwe kwizindlu.I-rotary pin plate igxininiswe kwi-axis yemoto ngokuthe ngqo.I-fixed yi-pin plate edibeneyo kunye nendlu.Izixhobo zondliwa kumatshini ukusuka kwiziko kwaye zikhutshwe kwi-outlet yayo ekwicala le-tangential.Okwangoku, impembelelo enzulu yenzeke phakathi kwezikhonkwane ezigxininiswe kwi-motor kunye nezikhonkwane kwizindlu.b, ipleyiti yemoto kunye nezikhonkwane kwizindlu c, izikhonkwane ezigxininiswe kwi-motor kunye nezindlu Ngaloo ndlela amanye amaphepha e-endosperm abangelwa yi-roller egudileyo akhululwe kwaye abe ngumgubo, enye i-semolina yegranular idilike ibe ngumgubo okanye iwele kwi-bran.I-rotor i-dynamically balanced kwaye ipeyintwe nge-lacquer yokutya ecacileyo ukukhusela ukurusa.Imiphezulu yezikhonkwane ezichaphazelayo ziphathwa ubushushu ukuqinisekisa ukuxhathisa ukunxiba.

Iimpawu Uyilo olukumgangatho ophezulu kunye noyilo olugqwesileyo.

1. Umatshini uza kunye ne-rotor elungeleleneyo, eqinisekisa ukusebenza kakuhle.

2. Izindlu zensimbi ezidibeneyo kunye nezinto ezichasene nokunxiba ziyamkelwa kwesi sixhobo.Ukomelela okugqwesileyo kukhokelela kwimirhumo yolondolozo enyiniweyo.

3. Isithinteli sempembelelo senziwa ngokoyilo lwethu oluphambili.Umatshini wokucubungula ophezulu kunye nobuchule buqinisekisile ukuchaneka okunqwenelekayo kunye nomgangatho wemveliso.

4. Imiphezulu yezikhonkwane ezichaphazelayo ziphathwa nge-thermal ukufikelela ukuxhathisa okunqwenelekayo.

5. Izikhonkwane ezingqukuva kunye nezikhonkwane zesikwere zinokuzikhethela kwiipropati ezahlukeneyo ezidlulayo kunye nokuqina kwempembelelo.

6. Umgangatho ophezulu wemoto wamkelwa kwi-detacher yempembelelo ukuqinisekisa ukuba umatshini usebenza ngokuzinzile.

7. Indawo encinci iyafuneka ukufakelwa kwesi sixhobo sokwenza umgubo, kwaye iintlobo ezimbini zokufakela zikhethwa.Inokuthi ifakwe kwi-gravity system yokuhambisa okanye ifakwe kumbhobho wokuhambisa umoya.

8. Akukho luthuli oludadayo luya kuveliswa kwaye ukulungiswa nokusebenza zombini kulula kakhulu.

9. I-detatcher yempembelelo ifumaneka kwiindidi ezimbini zobukhulu kunye namandla.

10. Umbhobho wokudlula kunye nokutshintsha umda ohambelanayo ongenisiweyo ufakiwe.Ngaloo ndlela xa umatshini uyeka, inkqubo yokusila inokuqhubeka isebenza.

11. Umphezulu wepini yentsimbi ye-carbon alloy ephantsi, emva kokunyangwa ngeendlela ze-nitriding kunye ne-carbonization, sele ichasene nokunxiba.

Isicelo

Ukusetyenziswa ngokubanzi kwiimveliso zomgubo zanamhlanje ukwandisa ukutsalwa komgubo kunye nokuncedisa.Iisayizi ezimbini zoomatshini bezakhono ezahlukeneyo.Iindidi ezimbini zokufakela zinokuzikhethela: zixhaswe kwi-gravity inlet, inqunyanyiswe xa ifakwe kumgca we-pneumatic.

isixhobo parameter

| Uhlobo | Umthamo(t/h) | Isantya sokujikeleza(r/min) | Ububanzi (mm) | Inani lePin eRound | Inani lePin yesikwere | Amandla(kw) | Ubungakanani bobume LxWxH (mm) |

| FSJZ43 | 1.5 | 2830 | 430 | 80 | 3 | 576×650×642 | |

| 2.5 | 2890 | 430 | 80 | 4 | |||

| 4 | 2900 | 430 | 80 | 5.5 | |||

| FSJQ51 | 1 | 2910 | 510 | 192 | 64 | 5.5 | 576×650×642 |

| 1.7 | 2910 | 510 | 192 | 64 | 7.5 | ||

| 2.8 | 2930 | 510 | 192 | 64 | 11 | ||

| 4 | 2930 | 510 | 192 | 64 | 15 |

Ukupakisha kunye nokuhanjiswa